Architectural Plumbing Expertise for Modern Builds

You’re sketching sleek lines and open spaces, yet the unseen water pathways still puzzle you. Architectural plumbing isn’t just pipes—it’s spatial logic, flow rates, and codes woven into design.

When questions bubble up about vent stacks or grey-water loops, browsing the practical discussions on Dan’s Plumbing can ground your ideas in real-world detail while you keep refining those bold floor plans. That clarity will echo through every faucet you specify.

Future-Proof Plumbing Strategies

Competitive construction timelines demand plumbing that thrives for decades, resists regulation shifts, and adapts to new technologies arriving faster than building owners can blink today.

- Adopt modular manifolds that make branch additions simple, letting future tenants reroute water without demolishing finished walls or ceilings during inevitable programming changes.

- Specify wide-band pressure ratings so pipes tolerate municipal upgrades, reclaimed-water tie-ins, and smart-valve retrofits that sometimes spike line pressure above original design limits.

- Choose universal communication protocols—BACnet, Modbus, or MQTT—inside leak detectors, meters, and pumps, guaranteeing tomorrow’s cloud platforms can harvest data without expensive gateway hardware.

- Plan service corridors large enough for robotic inspection crawlers and pipe-lining equipment, safeguarding against slab cuts when codes someday outlaw certain solder alloys.

Review market insights such as NY-Engineers’ future-proofing guide and weave their recommendations into bid documents, demonstrating foresight that clients immediately recognize and reward with repeat work.

Modern Water Supply Basics

Behind every splashy architectural rendering is a humble pressure zone calculation, ensuring top-floor fixtures receive consistent flow without cavitating recirculation pumps or starving fire risers.

Dual Subsystems Explained

Supply delivers conditioned freshwater while drainage gravity-whisks wastewater; cross-connection control devices vigilantly maintain the invisible but essential separation that architects often overlook during schematic design.

Why Pressure Matters

Urban towers often demand break tanks or variable-frequency booster sets to hold delivery between forty and sixty psi, eliminating fixture hammer and premature valve erosion.

Emergency Shutoff Strategy

Label main and branch isolation valves conspicuously, allowing facility teams to confine midnight leaks to single zones instead of flooding priceless finishes throughout contiguous tenant spaces.

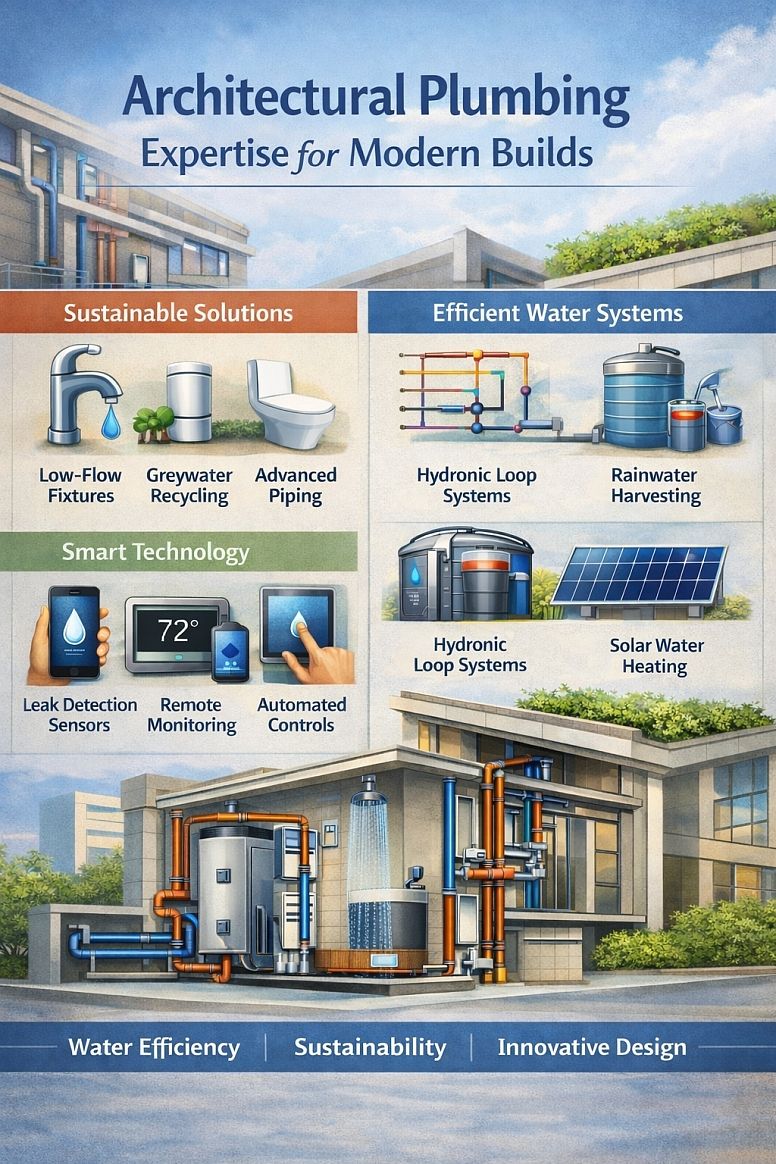

Sustainable Fixture Selection

Specifying faucets today is about balancing water stewardship, tactile experience, and brand storytelling, not merely matching chrome finishes with the faucet next door.

- Low-flow aerators inject air, trimming consumption up to fifty per cent while maintaining satisfying stream coherence that guests equate with luxury spa experiences.

- Dual-flush toilets slash annual water usage dramatically, letting patrons choose the volume appropriate for waste type without feeling lectured or inconvenienced.

- Sensor-activated taps eliminate idle run times in corporate restrooms, contributing measurable reductions to building Environmental, Social, and Governance scorecards coveted by investors.

- Sustainable materials such as recyclable stainless or bio-resins ensure cradle-to-cradle life cycles, aligning with LEED credits and growing circular-economy procurement mandates.

Consult life-cycle cost calculators before specifying; over ten years, efficient fixtures routinely recoup premiums through reduced utility charges and deferred replacement frequency.

Greywater and Rainwater Integration

Architects seeking net-zero water performance increasingly weave greywater loops and rooftop rain harvesting cisterns into base building infrastructure rather than as unpredictable alternates.

Capture Opportunities

Laundry, shower, and lavatory drains produce soap-rich greywater ideal for sub-surface irrigation after filtration, cutting potable demand and lowering storm-sewer impact fees.

Treatment Technologies

Simple cartridge filters suffice for irrigation, but membrane bioreactors or UV polishers may be mandated when reuse includes toilet flushing within occupied spaces.

Design Coordination

Early structural loading allowances for cisterns, plus dedicated purple-pipe chases, avert costly change orders once steel has been detailed and reinforcing scheduled.

Artistic Exposed Pipe Aesthetics

Visible piping transforms from mere utility to sculptural statement when designers intentionally celebrate alignment, finish, and rhythm instead of hiding everything behind gypsum.

Material Choices

Brushed copper, matte-black steel, or powder-coated PEX rails sync beautifully with industrial loft themes, providing honest materiality that resonates with contemporary occupants.

Pattern and Rhythm

Intentional offsets, ninety-degree turns, and repeated valve silhouettes echo architectural gridlines, turning mechanical discipline into a visual narrative that guests instinctively appreciate.

Maintenance Considerations

Exposed runs simplify inspection and leak detection, yet require specifying UV-stable materials and tamper-resistant hangers to withstand public interaction over building life.

Smart Leak Detection Technologies

Insurance carriers now discount premiums when certified smart sensors continuously monitor plumbing, automatically isolating zones and alerting managers the instant moisture appears.

- Point-of-use discs slide beneath sinks, water heaters, and laundry appliances, sounding local alarms while relaying alerts through Wi-Fi or LoRa gateways.

- Inline shutoff valves pair with cloud analytics, interpreting flow signatures to distinguish dishwasher cycles from catastrophic pipe bursts, triggering autoshutdown only when warranted.

- Cable sensors snake along server-room perimeters, detecting condensation or sprinkler discharge early enough to save millions in electronics replacement costs.

- Predictive dashboards rank leak probability by fixture age and usage, allowing proactive gasket swaps during planned downtime rather than disruptive emergency calls.

Green Tech Plumbing’s smart detection overview details deployment densities and maintenance tips that facility teams can implement without specialized instrumentation training.

Efficient Maintenance Scheduling

Sustainable performance depends less on glamorous specifications and more on disciplined maintenance calendars that convert surprise failures into predictable, budgeted service routines.

- Daily inspections spot odd odors, gurgles, or pressure swings, letting staff tackle minor blockages before they morph into reputation-damaging restroom closures.

- Weekly pressure testing verifies booster pumps, expansion tanks, and backflow preventers operate within design tolerances, extending equipment lifespan significantly.

- Monthly corrosion scans using ultrasonic probes reveal thinning pipe walls invisible to the eye, informing timely epoxy lining rather than disruptive replacement.

- Annual capital reviews align fixture refresh cycles with tenant improvement budgets, ensuring synchronized downtime and minimal revenue interruption for owners.

Digital CMMS platforms, such as those in the ServiceChannel checklist, sequence tasks automatically, generating evidence for warranty claims and ESG auditing alike.

Integrated Bathroom Innovations

Luxury restroom suites now rival boutique hotel amenities, blending wellness technology, acoustical privacy, and touch-free convenience within the building core’s most heavily trafficked zones.

Smart Mirrors

Backlit displays deliver environmental metrics, occupancy indicators, and branded content, doubling as anti-fog vanity lighting that reduces separate fixture counts and simplifies wiring.

Acoustic Zoning

Sound-masking ducts with micro-perforated liners damp plumbing clang while comforting users, proving mechanical engineers can materially influence perceived restroom hospitality quality.

Universal Accessibility

Adjustable-height basins, motion-reach dispensers, and contrasting color cues surpass code minimums, demonstrating genuine inclusivity instead of merely achieving checkbox compliance.

Pipe Material Comparisons

Selecting copper, PEX, stainless, or CPVC is rarely a binary decision; optimal schemes often hybridize materials, matching strengths to each zone’s thermal and chemical realities.

Copper offers antimicrobial properties and fire resistance, yet commands premium pricing and can suffer pinhole leaks where water chemistry is aggressive or velocity too high.

PEX installs quickly with fewer fittings and resists freeze fractures, but ultraviolet sensitivity demands careful routing away from skylights and long-term exposure to daylight.

Stainless steel excels in industrial kitchens and hospitals thanks to chlorine resistance, though fabrication labor and specialized tooling influence overall project economics significantly.

CPVC remains cost-effective for hot domestic loops, yet solvent welding requires stringent ambient-temperature control during curing to guarantee reliable joint integrity.

Cross-Disciplinary Design Collaboration

Plumbing discipline reaches full potential only when coordinated early with architects, structural engineers, and technology consultants, eliminating spatial clashes before they stall field crews.

Architectural Synergy

Aligning fixture locations with façade rhythms prevents awkward soffits, while shared 3D models let designers highlight exposed risers as honest expressions of building mechanics.

Structural Integration

Regular clash detection meetings confirm pipe sleeves through beams align with engineered moments, avoiding costly field core-drilling once concrete forms are already erected.

Digital Workflows

Common data environments enable real-time markups, ensuring last-minute sprinkler head shifts cascade automatically to plumbing coordination drawings without manual transcription errors.

Closing Flow

Your building’s lifespan depends on the choices you make today. Prioritize adaptable layouts, monitor systems continuously, and schedule data-driven upkeep to minimize surprises.

For comparative insights on real-world installations, browse the industry reviews before finalizing specifications. With informed decisions, you ensure performance, resilience, and responsible water stewardship for decades to come.